The West Gate Bridge is a key part of Melbourne’s transport infrastructure, connecting the east and west sides of the city since it was opened to traffic in 1978. But how does VicRoads ensure the bridge stays in good condition?

Some history

The 2.5km long West Gate Bridge consists of two concrete box girder approach viaducts, 871m and 670m long, and an central 848m cable stayed steel box girder span over the Yarra River. The pier height varies, with a maximum height is 48m.

Except for the portion over the river, practically the full length of the bridge is above vacant land and can be accessed from below by means of elevated work platforms.

But for the portion of the bridge over the river, four permanent maintenance platforms were provided beneath the steel spans.

Operated from two runway beams, three of the platforms dated back to the construction of the bridge in the 1970s, with a fourth installed in 1995, these gave access for routine inspections, as well as minor works such as washing and patch painting.

Upgrade time

In 2006 the State Government announced that they would upgrade the West Gate Bridge to carry an additional lane of traffic, taking it to five in each direction.

Scaffolding was setup underneath the bridge to allow the necessary strengthening works to take place.

Including suspended platforms.

And an elevated lunch room!

The most noticeable change being the outriggers added to the steel span to support the load from the additional traffic lane.

But this presented a problem – it would block the passage of the existing maintenance platforms.

Two options were considered – a replacement system of maintenance platforms, or the acquisition of a mobile bridge inspection platform that would be deployed as needed.

The solution – an upside down crane

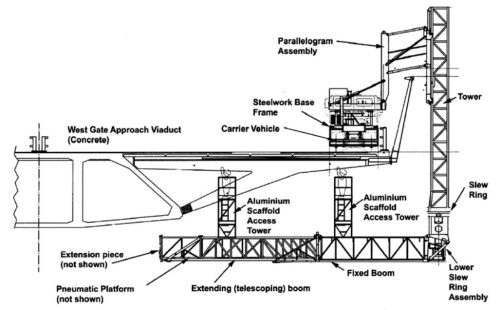

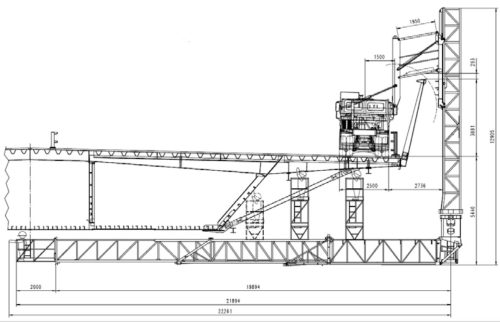

This weird looking thing is a MBI 200 under-bridge access unit, custom designed by Moog GmbH in Germany specifically for the Westgate Bridge.

The State Government boasting in a September 2012 media release.

Australia’s largest Mobile Bridge Inspection Platform will improve access for maintenance inspections on Victoria’s most iconic bridge, Minister for Roads Terry Mulder said today.

Roads Minister Terry Mulder announces a mobile bridge inspection platform will replace permanent hanging inspection platforms for the West Gate Bridge, providing more efficient and cost effective maintenance.

Mr Mulder said the mobile bridge inspection platform would replace permanent ‘hanging’ inspection platforms for the West Gate Bridge, providing more efficient and cost effective maintenance.

“Mobile bridge inspection platforms are becoming more and more common on large bridges around the world as sustainable and cost effective maintenance tools,” Mr Mulder said.

“I’m very pleased to launch this innovation in Victoria, which will provide a great cost saving, as we do away with expensive and heavy permanent inspection platforms that span nearly one kilometre.

“It also improves access to all areas under the West Gate Bridge with an expanding platform that can extend for 20 metres under the bridge deck.

‘This will make it is easier for maintenance inspectors to see more of the underside of the bridge and because it is mobile, they can manoeuvre it to exactly where they want to be,” Mr Mulder said.

In what can only be described as an ‘upside down crane’, the unit includes a 17 metre boom arm that extends over the bridge barriers and lowers the inspection platform in place.

In order to stabilise such a large operation, the base truck, at 12 metre in length, has six axles when in operation and weighs 37 tonnes.

“The Mobile Bridge Inspection Platform has come to Australia all the way from Germany and is a great example of Victoria delivering innovative solutions to manage key infrastructure well into the future.”

When in operation, the unit will require two lanes to be closed on the West Gate Bridge to complete an inspection. These will be conducted during off peak periods and at night to reduce delays to traffic.

The bridge inspection unit completed initial testing on the yet to open Nagambie Bypass.

Showing off the capability of the machine.

And looking like a transformer in the process.

The inaugural use on the West Gate Bridge was scheduled for Saturday 22 September between 6:00am and midday.

Two lanes of traffic being closed, while the machine was in use.

But following the successful commissioning of the unit, it is usually deployed in the dark of night, to minimise the amount of disruption to traffic.

Footnote: more details

Some facts and figures

– 12 metres long

– 2.5 metres wide

– 4.4 metres tall

– 37 tonne mass

– 800 kilogram maximum payload

– 20 metre long access platform

– 17 metre long boom arm

– 6 effective axles when in operation

The under-bridge access unit is mounted atop a Scania 8×4 chassis, with two auxiliary axles able to be lowered to provide additional stability to the vehicle while in use, removing the need for outriggers. Movement of the vehicle while deployed is via 200mm diameter hydraulic driven rollers bearing on the top of the one set of tyres, providing accurate creep control.

Along the boom modular aluminium access scaffold are provided to give access to the underside of the bridge. Additional equipment includes a 12Kva generator providing 415 and 240 volts to power tools, LED lighting, air compressor, water tank and pump, and a hydraulically operated telescopic lift.

Footnote: and other bridges

The West Gate Tunnel project recently used an under-bridge access unit to inspect Shepherd Bridge in Footscray.

West Gate Tunnel Project photo

But they used a ABC 150/LST unit built by Barin Italy, supplied by Ace Tower Group.

Further reading

- West Gate Bridge: mobile bridge inspection platform: Polymenakos, D; Silla Sanchez, J; Noonan, J; Austroads Bridge Conference; 2014

- Australia’s largest ‘upside down crane’ to improve maintenance inspections on West Gate Bridge: Victorian Government media release; 2012

- West Gate Bridge Strengthening Project: Australian Construction Achievement Award paper

- Delivery of MBI 200 to Melbourne: Moog GmbH

- West Gate Bridge: Ace Tower Hire

Great column! I’ve been inside the West Gate Bridge twice, while working as a journalist for the Sunday Herald Sun. The first time I entered through a door near the top of the bridge, which had access to a ladder down inside the bridge. It was dark, with small portholes sliced through the metal sections inside to allow maintenance workers to hop over from one section to another. It was like being inside the hull of a ship. Years later I was invited back again and went up a lift built against one of the piers. I changed into overalls in a change room suspended beneath the bridge, then walked up some steps that were suspended over the edge of the bridge to access the door. By this time the access portholes between the different sections were all widened into full doorways, so it was possible to walk the full length of the bridge interior, which was by then fully illuminated.

I understand there is still an elevator alongside one of the piers, though from the ground it’s difficult to see how it actually ascends the outside of the pier.

Glad you enjoyed it!

There are some photos showing the walkway inside the steel deck of the West Gate Bridge here:

https://acaa.net.au/wp-content/uploads/2020/02/West-Gate-Bridge-Strengthening-Victoria.pdf