In the inner Melbourne suburb of Kensington there is a flour mill – this is the tale of how the grain gets there by train.

Some history

Kensington has a long history of flour milling, as detailed in the ‘Kensington & Flour Milling Heritage Precinct’ section of the Melbourne Planning Scheme:

In the 1880s several new mills were built on the trunk railways including James Gillespie’s Kensington Roller Flour Mill of 1886-7, Kimpton’s Eclipse Hungarian Roller Flour mills of 1887, and Thomas Brunton’s Australian Flour Mills in 1893-4. Brokhoff biscuits located further south, was also built around 1890 with the intervening space filled with various stores and warehouses serving to milling and baking trade. James Minifie & Co (former head miller at Dight’s Falls Mill and Kempton’s) built his own Victoria Roller Flour Mill in 1906-7 in South Kensington.

With the Kimpton’s mill…

Developing into the flour mill operated by Allied Pinnacle today.

Kimpton’s original mill was burnt out and rebuilt in 1904 and became known as the Kimpton No. 1 Mill, until closed in 1971. The Gillespie mill was bought by Kimpton in 1904 following the liquidation of Gillespie’s Victorian interests, becoming Kimpton No. 2 Mill. It was refitted in 1913, closed in 1976 and demolished in 1982.

The Kimpton No. 3 mill was built in 1927 on the corner of Elizabeth and Arden Street. A merger of three prominent milling firms created Kimpton Minifie McLennan Pty Ltd in the 1960s, which was bought out by Allied Mills in 1981, then Goodman Fielder. As a result, a new mill was erected north of the silos in the 1990s.

Moving grain by train

Grain is grown across Western Victoria.

Being moved by truck from farm to silo.

Then loaded into trains.

Then off to the city.

Headed through the countryside.

Until the train enters Melbourne.

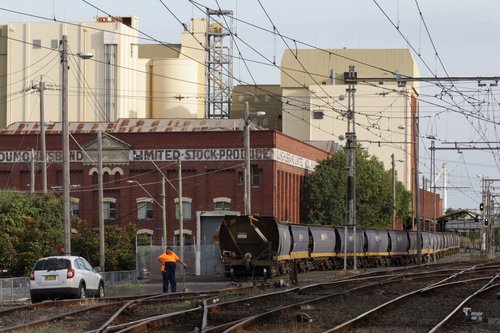

Grain trains take the freight tracks past South Kensington station.

Until they reach North Melbourne, where the engines have to run around to the other end of train.

With that done, it’s just a short trip over to Kensington station.

The train stops in the platform.

And is then pushed back into the flour mill siding.

The wagons are then pushed through the unloading shed.

Two wagons at a time.

With the grain being unloaded between the tracks via bottom discharge doors.

Until the entire train is done.

Once the train is empty, it’s time to change the points.

Then push the train back out onto the main line.

Then change ends, back to North Melbourne, change ends a second time, and finally back to the country for another load.

And all this while sharing the tracks with suburban trains on the Craigieburn line.

What is the grain turned into?

In 2011 Allied Mills described their operations at Kensington in a submission to the City of Melbourne for the Arden-Macaulay Structure Plan.

The Allied Mills Site has been an operational flour mill since 1887. Allied Mills manufactures and distributes milling based products including but not limited to:

a) flours for bread, cake, pastry, biscuits, noodle and culinary applications;

b) premixes for bread, cake, donut and culinary applications; and

c) specialty meals, semolinas and brans.The composition of the flour milling industry has changed drastically over the last century. In the 1870s there were 160 flour mills in Victoria which has now been reduced to three. Allied Mills owns and operates eight flour mills nationally, located in each Australian state. In Victoria, the sites are based in Kensington and Ballarat, with Kensington being one of the largest Australian sites and representing approximately one fifth of its total operations. It is therefore strategically essential to Allied Mills’ operations.

Allied Mills is an integral component of the Australian flour milling industry. Approximately 90% of the Australian flour milling industry is comprised of three major companies of broadly equal market share. These are Allied Mills, George Weston Foods and Manildra. Allied Mills presently services the vast majority of all multinational food manufacturer flour requirements in Australia, most of whom are common Australian household names. Further, Allied Mills holds a majority portion of the bulk flour market and significant portions of both the bagged flour market and bakery mix market.

By 2017 Allied Mills was processing 800,000 tonnes of wheat and speciality grains a year into flour and other products across their operations.

And how many trains?

Back in 2017 grain trains were visiting Kensington three times a week, each train made up of 20 wagons, each loaded with 55 tonnes of grain – or 3300 tonnes of grain a week.

Compare this how much grain a truck can move – between 16 and 65.6 tonnes – or the equivalent of 50+ trucks driving through suburban Kensington.

What about the future

With the warehouses around Kensington subject to the Arden-Macaulay Structure Plan, how long will a flour mill survive in the middle of a forest of apartments?

But a bigger problem is the sourcing of grain in Victoria following the Murray Basin Rail Project – flagged as an issue in 2017.

Exacerbating this issue is the change of rail gauge in western Victoria from broad gauge to standard gauge. As the rail line and siding at Kensington is broad gauge, the site can no longer accept grain delivery by train from western Victorian growers. This has the impact of reducing grain supply via rail and increasing grain delivery by truck increasing the truck movements at the site.

But there is a possible solution – transporting grain in containers.

Or the ‘nuclear’ option – relocation.

The Sydney experience

Until 2009 the Mungo Scott flour mill operated at Summer Hill in Sydney’s inner west, and was supplied by train by trains on the Rozelle goods line.

Until it was replaced by a new flour mill at Picton, south of Sydney, built on a greenfields site right beside the Main South railway line.

Which allows both the receival of grain and despatch of flour by rail.

I wonder how much longer until rising land values at Kensington leads to a similar move in Victoria?

Even if relocation is the long term preference, why can’t points be added on the UP side (city end) of the mill siding to prevent those trains using the Macaulay Rd crossing?

Two problems.

First is that there are two sets of tracks from Kensington towards North Melbourne:

– the ground level tracks normally used by suburban services for the City Loop,

– and the high level flyover towards North Melbourne platform 5/6 and the goods lines.

The grain train needs to use the high level tracks to head back west, but the sidings are beside the low level tracks.

Second problem is that the city end of the siding is at a different level from the main line, so it’d need to be rebuilt to connect.

I’ve often wondered how much it would cost to rebuild that flyover so that Down suburban services go under the flyover, eliminating the conflict between the two routes. It’s a little complicated by the presence of a road under the junction, but I’m sure it could be done. Admittedly it would’ve made more sense to have been done in pre-City Loop days when suburban trains went over the top and country trains went direct to North Melbourne. The whole North Melbourne junction (plus Spion Kop) is quite constrained, but it wouldn’t be that hard to design a much better junction that minimises conflicting moves.

As part of the Regional Fast Rail project they proposed works in this area to speed up country trains bound for Southern Cross:

https://wongm.com/2014/01/regional-rail-link-precursor-plans/

I expect you are correct about the relocation. It sounds like a very antiquated system to get the train into the siding to unload. I recently read how slow the train is to being grain to Melbourne and our port. It is not a great political story for the front of our newspapers, but our country really needs to invest in rail freight, especially where it is a no brainer, like freight between Melbourne and Sydney. I wonder how the fuel costs for the hundreds of trucks plying the highway between the two cities compare to the fuel costs for moving the same amount of freight by rail, including the add on local transport costs that could be involved with rail.

Sounds like the Murray Basin Rail Project:

https://www.bendigoadvertiser.com.au/story/6227190/murray-basin-rail-fail-fix-will-be-costly-says-expert/

The Mildura line was gauge converted but they ran out of money to do the entire job, so trains now have to make a 130 km detour via Ararat.

Is this going to be another North-East Line debacle? Spend money regauging a railway line, do the cheapest option and completely screw it up, and then spend a decade or more on remedial works that never quite fix the underlying problems?

Enjoyable read!

I grew up in the shadow of those silos, will be sad to see them go

Occasionally you’ll see silos converted into apartments:

https://www.architectureanddesign.com.au/news/hassell-transforms-industrial-silos-into-apartment

But it’s a costly job – so few developers follow through with their proposals.

https://www.thecourier.com.au/story/547497/gregory-st-silos-to-come-down/

[…] And a grain train headed to Kensington. […]

[…] First off here’s the link to Marcus’ site […]

worked at kimptons flour mills for 15 yrs , 6 yrs at barastoc over the rd from the mill and when that was bought by arnotts and moved to ballarat i moved to the flour mill in maintance till 1990 when the new mill started , i worked in no1, no2, and no3 mills , only some sections of no1 and no2 were still operating , no3 was fully operational , they were all roller mills , no2 and no1 mills when production stopped and they were stripped of machinary the roller mills had to be destroyed expecially 1st 2nd and 3rd brake roller mills , so that no one could buy them and start up a mill , they are the 3 critical roller k mills 1st, 2nd, and 3rd brake , the company was a family bussiness back in kimptons days and fathers and sons worked there all their lives , after kimptons this all changed and was no longer a close family bussiness , when i started there in 1974 kimptons basicially owned the whole block down to the the creek and most of elizabeth st i have many pics of no 3 mill running and of the construction of the new mill from 1988-1990 , have pics of the roller mill flour , top flour elevators , silos, basement etc , all the mills were line shaft driven where as the new mill had no line shafts , was a great place to work

just reading about the kimpton mills where i worked ,and at the start it says number 2 mill was demolished in 1982 , THATS NOT CORRECT it was demolished in approx 1986 , as the new mill that replaced it no 4 only became operational in 1990 no 2 mill was not operating in 1982 but it was not demolished in 1982 , cheers steve

Thanks for the correction Steve!

Yes, Steve that’s correct, I first arrived at the site on April 22, 1986, and the old mills were demolished, the only building that had to be removed then was the old workshop, which was carried out by Raffety Demolition. I would think I still have the movies I took for four years during some demolition and all of the refit of the silos both wooden and concrete silo conveyors etc. Also construction of the Flour mill and bulk building. I was on this site till about Feb / Mar 1990

Cheers

Peter

Great article. It brought back my memory of working in the Minifie’s lab, circa 1969, in Kensington, as it was in the process of amalgamating with another firm up the road.

The trucks arrived beside the lab & you stepped through the door to take samples.

The mill also made stock feed such as pig pellets & dog biscuits, etc..

Thanks for sharing Michael!

I left Minifies in 1969 after 17 years in the latter years with the JM Stockfeeds prior to the Amalgamation.

[…] decade ago Pacific National still had the contract to transport grain by rail to the flour mill at Kensington. Southern Shorthaul Railroad won the contract in November […]